OFFER

| Drying and disinfecting cabin type KSD |

Drying and disinfecting cabin type KSD

Type KSD - drying and disinfecting cabin for gloves, shoes and clothes

Advantages:

- Disinfection, destruction of micro-organisms and their spores (ozonation)

- Does not interfere with interior décor

- Carries odours outside the room

- No need for purchase of additional equipment

- Multifunctionality, high quality and high performance of drying

- Innovative solution of air circulation in the cabin during drying process, low operating costs

APPLICATION

I. Industry and Services

- Technological processes

- Abattoirs, slaughterhouses (hygienic certificate)

II. Recreation, sports - tourism and winter sports

CHARACTERISTICDATA OF CABINS MANUFACTURED BY ZPUG IZOTERMA

| No. | Type 230V 50Hz |

Dimensions − mm | Power kW |

Numbers of doors | Weight without equipment kg |

Cabinet's material | |||

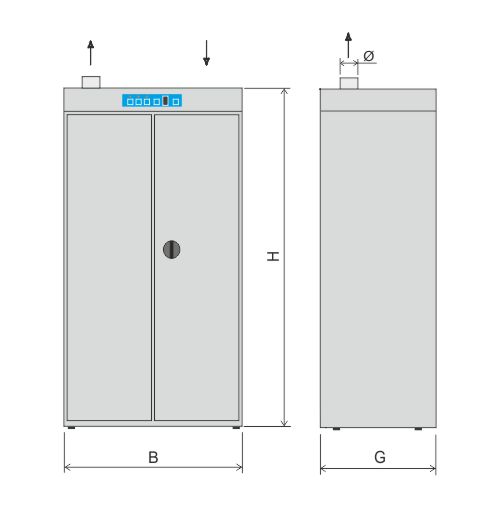

| B | G | H | Ø | ||||||

| 1. | KSD - 80 | 800 | 600 | 1825 |

100 | 2,0 | 2 | 66,0 | Galvanized varnished metal sheet |

| 2. |

KSD - 100 | 1000 | -''- | -''- | -''- | 2,0 | 2 | 76,0 | |

type KSD - Drying and disinfecting cabin for gloves, shoes

The structure of the cabin and its operational equipment provides for numerous possibilities of its application: heating, burning, drying, humidifying, disinfecting. It allows performing technological operations pertaining to materials, raw materials, elements as well as technological operations in the production phase of industrial products and products in agricultural-food processing industry.

DESIGN

Cabin design - self-supporting, made of sheet steel, galvanized; painted, welded; two-leaf doors with lock. Internal equipment of the cabin - made of steel.

INSTALLATION

Set the cabin on an even surface, check the level on the ground, mount the spiro-pipe into the ventilation grille and then connect the cabin to a 230V socket.

EQUIPMENT OF THE DRYING CABIN

a - standard equipment, b - operating equipment , c - special equipment (optionally: ozone generator, UV lamp).

DRYING PROCESS

Heating and ventilation unit and controller is located at the top of the cabin in separate chamber – this protects against accidental damage and is also safe for the user of the cabin.After switching the cabin on, air is drawn through the turbine-fan from the immediate surrounding through openings in the cover of the ceiling and then pushed into an electric heater. The heated air is directed – with high speed – down towards the floor, and then reflected back from the floor – it directed upwards. This drying process works on the charge which is to be dried not only from the top, but also from the bottom; turbulent air flow penetrates every possible nook and cranny of the charge which is to get dried.

At the same time, separation of the air occurs in the cabin. A portion of the air is directed outwards, drawing out moisture from the cabin to the ventilation duct – and the remaining part of the air is re-introduced into circulation. The turbulent air flow in the cabin causes that the drying process is precise and relatively short (therefore economical). Special cabin equipment (c) allows for the disinfection of the charge (ozone generator).

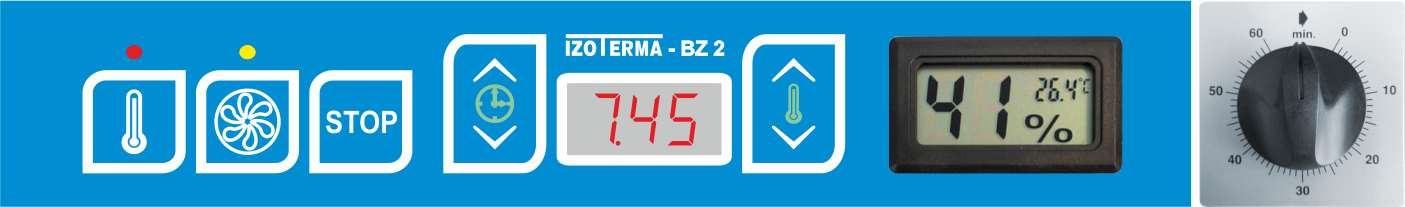

CONTROL

Electronic intuitive controller for programming of: time, temperature; humidity indicator.

CERTIFICATE

CE – Declaration of Conformity, Certificate of Health Quality NIH in Warsaw (KSD-K type).

WARRANTY, SERVICE

Manufacturer's service – problem-free.

STORAGE AND TRANSPORT

The cabin must be transported in an upright position – (working position) on Euro pallet, without high-stacking of cabins. It should be noted that both the transport and storage of the product is to be performed in a safe manner, and the area of storage should not be moist, without the possibility of mechanical damage (during placement, uncontrolled movement, shock, tipping over, etc.). Apart from these, there are no specific recommendations regarding safe storage and transport. We reserve the right to change the design of the product.

| ZAKŁAD PRODUKCJI URZĄDZEŃ GRZEJNYCH 55-002 Łany k. Wrocławia, Poland ul. Odrzańska 14 |

Tel.+48 71-318-58-95 Tel.+48 71-318-58-96 e-mail: izoterma@izoterma.com.pl |